Mesh fabrics come in many different weights and types and are used for different things such as sportswear, tent, plush toy, and even practical uses such as workwear and equipment - but today we'll be discussing the polyester mesh we sell, which is perfect for bags and accessories!

The following article provides an overview of polyester mesh, discusses its properties, benefits and applications.

What is mesh fabric?

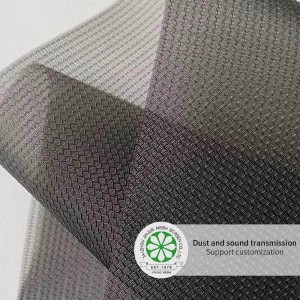

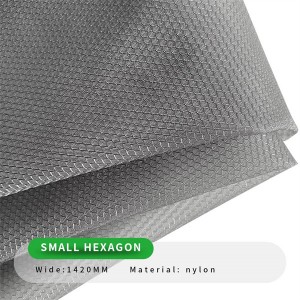

Mesh is a loosely woven fabric, usually made of polyester or nylon (although when used in industry, it can even be made of materials such as metal and rope!) ), which has uniform holes on its surface, and the size may vary depending on the type of fabric mesh. Synthetic materials such as polyester ensure that the fabric is strong, can withstand the wear and tear of use, and has strength due to its loose weave and structure, but still remains flexible.

Because of the perforated surface, it is always breathable, no matter what it is made of, so it can be used for sportswear or bags and accessories that contain wet or damp items so that water droplets can dry or escape.

Properties and Benefits of Polyester Mesh

Polyester fabrics have many advantageous properties over other mesh materials that make them suitable for a variety of industrial, commercial and recreational applications

Ease of use and accessibility. Polyester is a common fiber found in most textile manufacturing facilities. When treated with lightweight resins, webs are easy to install (sewn) and clean, reducing the extra time and labor required for integration and maintenance.

Dimensional stability. Polyester fibers exhibit good elasticity, which allows the material to return to its original shape after stretching by as much as 5-6%. It is important to note that mechanical stretching is different from fiber stretching. Highly elastic materials can be designed with dimensionally stable yarns.

Durability. Polyester mesh fabrics are highly elastic and have inherent resistance to damage and degradation caused by acidic and alkaline chemicals, corrosion, flame, heat, light, mold and mildew, and abrasion. Factors such as yarn weight (denier), tangles and filament count are all critical in determining durability.

Hydrophobicity: Polyester webs are hydrophobic - i.e., tend to repel water - which means better pigment absorption (meaning easier dyeing operations - compared to Type 6 or Type 66 nylon ) and drying time (meaning better moisture wicking properties).

In short, these properties lend themselves to use in a wide range of materials, including applications involving outdoor and harsh environmental conditions.

Fabric Applications

As mentioned above, polyester mesh fabrics are versatile. Some of the industries that frequently use this material for their parts and products include

The aerospace, automotive and marine industries for curtains, cargo nets, seat belts, seat support substrates, literature bags and tarpaulins.

The filtration industry for filters and screens.

Medical and healthcare industries for curtains, braces, IV bag holders, and patient bibs and support systems.

Occupational safety industry for cut-resistant clothing, high-visibility undershirts and safety signs.

Recreational sporting goods industry for aquaculture equipment, camping supplies backpacks, etc.), golf simulator impact screens and protective screens.

The exact performance exhibited by the polyester mesh fabric used depends on the application and the needs of the industry.

Where can I buy mesh fabrics?

At Jinjue, we are proud to offer a variety of special polyester mesh fabric to meet all your needs.

For more information about the mesh fabric, welcome to write to us at Jane@cn-screen.com. We will be happy to help you out!

英文版主图6-300x300.jpg)