One of the pillars of Jinjue’s knit fabrics product line is polyester mesh. This versatile material is used in a variety of industrial and commercial applications, ranging from the aerospace and automotive sectors to the marine and medical sectors as well as the indoor and outdoor recreational trade.

The following article provides an overview of polyester mesh, discussing its properties, advantages, and applications. If you’re planning to buy mesh, be sure to read on.

An Overview of Polyester Mesh Fabric

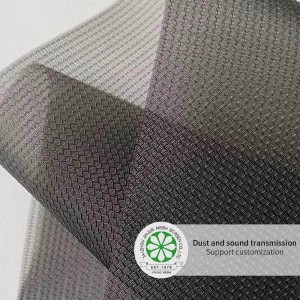

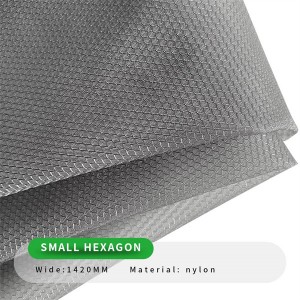

The term “knit mesh fabric” is a general expression used to describe material that is constructed with an open hole structure through the process of knitting. Beyond this broad characteristic, the design of a specific knit mesh material can vary from others in regard to yarn, material weight, aperture opening, width, color, and finish. Polyester yarn is one of the most commonly used fibers in the manufacture of knit mesh fabric.

Polyester consists of flexible, synthetic polymer fibers created through a chemical reaction between alcohol, carboxylic acid, and a petroleum byproduct. The resulting fibers are then stretched and oriented together to form a strong yarn that naturally repels water, resists staining, ultraviolet degradation, and holds up to frequent use.

Properties and Advantages of Polyester Mesh Fabric

Compared to other mesh materials, polyester fabric exhibits a number of advantageous properties that make it suitable for use in a variety of industrial, commercial, and recreational applications, such as:

Ease of use and accessibility. Polyester is a common fiber available at most textile manufacturing facilities. When treated with a light resin the mesh material is easy to install (sew) and clean, thus reducing excess time and labor required for its integration and maintenance.

Dimensional stability. Polyester fibers demonstrate good elasticity, which allows the material to return to its original shape after it is stretched by up to 5–6%. It’s important to note that mechanical stretch is different from fiber stretch. One can design hi-stretch material using dimensionally stable yarns.

Durability. Polyester mesh fabric is highly resilient, offering inherent resistance to damage and degradation stemming from acidic and alkaline chemicals, corrosion, flames, heat, light, mold and mildew, and wear. Factors such a yarn weight (denier), entanglement, and filament count all are critical in determining durability.

Hydrophobicity: Polyester mesh is hydrophobic—i.e., tends to repel water—which translates to superior pigment absorption (meaning easier dyeing operations- as opposed to type 6 or 66 nylon) and drying times (meaning better moisture-wicking properties).

Altogether, these characteristics suit the material for use in a wide range of applications, including ones involving outdoor and demanding environmental conditions.

Fabric Applications

As indicated above, polyester mesh fabric is highly versatile. Some of the industries that regularly employ the material for their parts and products include:

The aerospace, automotive, and marine industries for curtains, cargo nets, safety harnesses, seat support substrates, literature pockets, and tarps.

The filtration industry for filters and screens.

The medical and healthcare industries for curtains, braces, IV bag supports, and patient slings and support systems.

The occupational safety industry for cut-resistant clothing, high-visibility vests, and safety flags.

Recreational sporting goods industry for aquaculture equipment, camping supplies backpacks, etc.), golf simulator impact screens, and protective netting.

The exact properties exhibited by the polyester mesh fabric employed depend on the needs of the application and industry.

英文版主图6-300x300.jpg)